Table of Contents

Introduction: How the Global Supply Chain Quietly Shapes Modern Life

The smartphone in your hand traveled through fifteen countries before reaching you. The coffee you sipped this morning crossed three continents. The medicine in your cabinet passed through a dozen specialized facilities on four different shores. These journeys happen millions of times each day, weaving an invisible web that holds our world together. This is the Global Supply Chain, a building block of the global economy so fundamental that its absence would unravel modern civilization within weeks.

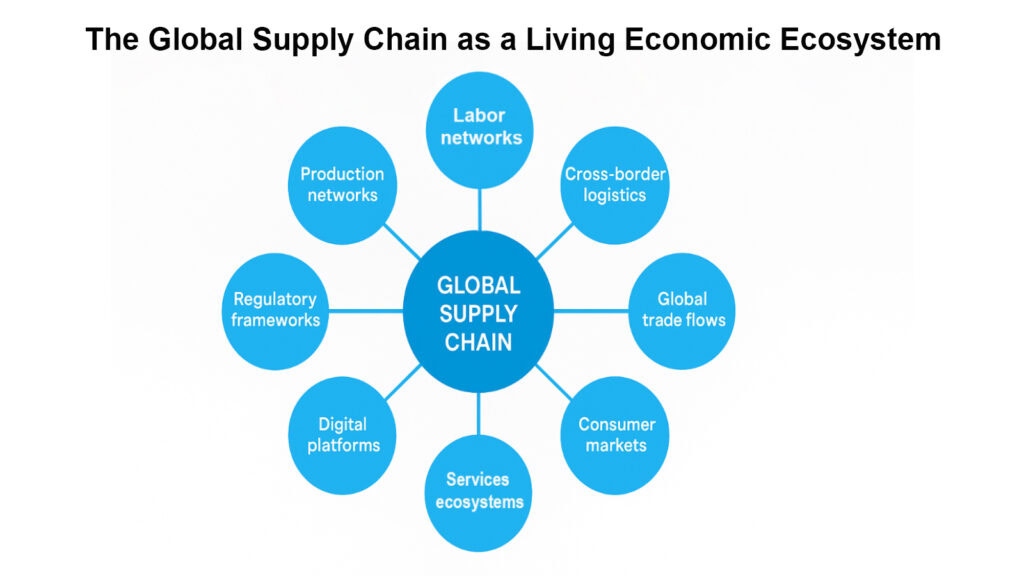

The Global Supply Chain connects buyers and sellers across every border. It transforms raw materials into finished products through a choreography of ships, planes, trucks, warehouses, and factories. Most people notice it only when it breaks, during a shortage or delay. But it operates every moment, a circulatory system for the entire planet.

This system shapes what we buy, how we work, and what we expect from tomorrow. Nations depend on it for security and prosperity. Companies rise or fall based on how well they navigate it. Understanding how this system works means understanding the forces that will shape the next generation of global growth and innovation.

Global Supply Chain Connections with Building Blocks of Gloal Economy

| Building Blocks Of The Global Economy | Relationship with Global Supply Chain |

|---|---|

| Global Trade | Enables 90% of international trade through maritime routes, moving over $1.5 trillion in goods annually through US ports alone. |

| Labor Migration | Employs hundreds of millions worldwide, with skilled labor following supply chain hubs and manufacturing centers. |

| Global Tech Innovation | AI-enabled management reduces logistics costs by 15%, cuts inventory by 35%, and improves service efficiency by 65%. |

| Natural Resources and Energy | Requires rare earth elements, specialized chemicals, and energy inputs from concentrated global suppliers. |

| Governance and Institutions | Trade agreements and regulations provide rules enabling cross-border operations. Policy changes immediately reshape networks. |

| Global Financial Systems | Requires trade finance, currency markets, and payment systems for cross-border transactions and working capital. |

| Geopolitics | Political tensions drive nearshoring to Mexico and Vietnam, restructuring production networks along political lines. |

| Demographics | Population growth and aging shift demand patterns, determining where factories locate and products move. |

| Climate and Sustainability | Environmental pressures drive transformation, with companies achieving 12% carbon intensity reductions through optimization. |

1. The Global Supply Chain as a Living System of Constant Motion

The Global Supply Chain never sleeps. At any moment, forty thousand cargo ships cross the oceans. Five hundred million packages move through sorting facilities. Three billion data points flow through tracking systems. This perpetual motion creates the rhythm of modern commerce, a pulse that keeps economies alive.

Motion defines resilience in this system. When a port closes, ships reroute. When a factory slows, another accelerates. Ports become nodes in a nervous system that senses pressure and redirects flow. Trucks become arteries carrying goods to consumption points. Data streams become synapses transmitting information about what needs to move next.

Just-in-time manufacturing relies on goods arriving precisely when needed, reducing inventory costs. Fast fashion responds to trends within weeks. Pharmaceutical supply chains maintain cold chain integrity across continents. Speed has become a competitive advantage that only constant motion can provide.

Yet stopping carries enormous cost. When COVID-19 shut down factories in early 2020, recovery took months. Average delivery times for raw materials now take 81 days compared to 65 days before the crisis, a 25% increase that highlights how difficult restoring momentum becomes once lost.

Global Supply Chain Motion Components

| Motion Component | Function and Impact |

|---|---|

| Maritime Networks | Handle 90% of international trade through continuous ocean freight connecting manufacturing and consumer markets. |

| Air Freight Corridors | Provide speed for high-value, time-sensitive goods like electronics, pharmaceuticals, and perishables. |

| Ground Transportation | Complete last-mile delivery and connect inland production to ports with flexibility ships cannot provide. |

| Warehouse Operations | Act as strategic buffers and sorting hubs, with automated facilities processing tens of thousands of items hourly. |

| Digital Coordination | Enable real-time tracking, inventory management, and route optimization through AI-powered platforms. |

| Labor Networks | Keep goods moving through manual tasks and decision-making at every node from ports to final delivery. |

2. How the Global Supply Chain Creates Hidden Dependencies Across Nations

No country stands alone in the modern economy. The Global Supply Chain has woven nations into a fabric of mutual dependence so complex that disruption in one region reverberates across continents. This interdependence creates both opportunity and vulnerability.

The semiconductor industry reveals this dependency starkly. Taiwan produces 92% of the world’s most advanced chips below 10 nanometers. South Korea manufactures an additional 8%. One earthquake, one political crisis, one trade restriction can cascade through this concentrated supply chain and impact every device requiring advanced computing.

This pattern repeats across industries. Pharmaceutical active ingredients concentrate in India and China. Medical equipment manufacturing clusters in Malaysia and Singapore. Rare earth elements come predominantly from Chinese mines. Each concentration point represents a potential chokepoint where disruption can halt production worldwide.

The pandemic demonstrated what happens when dependencies break. Factory closures in Asia led to shortages in Europe and North America within weeks. Automotive production stopped worldwide due to missing semiconductors. Companies realized they had mapped only direct suppliers while remaining blind to deeper dependencies. Research shows that only 16% of businesses know all their suppliers.

Geopolitical tensions now weaponize these dependencies. Export controls on advanced semiconductor equipment aim to slow technological progress in rival nations. Trade wars force companies to choose sides and rebuild supply networks along political lines. The Global Supply Chain, once optimized for efficiency, now must balance efficiency against security.

Global Supply Chain Critical Dependencies

| Sector | Nature of Dependency |

|---|---|

| Semiconductors | Taiwan and South Korea control 100% of advanced chip production below 10 nanometers with no alternative sources. |

| Pharmaceuticals | Active ingredients concentrate in India and China, creating vulnerabilities during health crises. |

| Rare Earth Elements | China dominates mining and processing of materials essential for batteries, magnets, and electronics. |

| Energy Components | Solar panel and battery production concentrate in Asia, particularly China’s polysilicon supply chain. |

| Food Systems | Global grain markets depend on exports from handful of countries; fertilizer production concentrates regionally. |

| Shipping Infrastructure | Limited major carriers control vessel capacity; key chokepoints handle vast percentages of global trade. |

3. Why the Global Supply Chain Thrives on Data, Intelligence, and Prediction

Behind every physical movement lies a digital brain making thousands of calculations. The Global Supply Chain has evolved beyond logistics into a data science challenge. Companies now compete on predicting what needs to move, when, and how.

Modern supply chains generate staggering data volumes. IoT sensors track temperature, location, and condition in real time. Point-of-sale systems capture consumer patterns. Weather satellites affect routing decisions. Combining these streams creates predictive power that transforms reactive logistics into proactive orchestration.

AI algorithms process information at speeds humans cannot match. Machine learning models forecast demand with 30% to 50% accuracy improvements. Companies using AI-driven analytics report reducing forecasting errors by at least 20%. Digital twin technology creates virtual replicas of entire networks, allowing managers to simulate disruptions before implementing real changes.

The AI in supply chain market projects reaching $41.23 billion by 2030, growing at 38.8% annually. Early adopters report logistics costs dropping 15%, inventory falling 35%, and service efficiency improving 65%. These gains come from automation and real-time analytics allowing networks to self-optimize continuously.

Digital twins provide perhaps the most powerful intelligence tool. These virtual models mirror physical supply chains in real time. Managers can test scenarios without disrupting operations. Siemens uses digital twin environments to model over 500 production scenarios daily, reducing logistics cost volatility by 14%.

Human expertise remains crucial despite automation. Algorithms optimize within parameters, but humans set strategy. The most effective supply chains combine computational power with human judgment.

Global Supply Chain Intelligence Technologies

| Technology | Application and Impact |

|---|---|

| Artificial Intelligence | Forecasts demand and optimizes inventory, reducing inventory 35% and costs 15% through pattern analysis. |

| IoT Sensors | Track location, temperature, and handling conditions enabling immediate response to deviations. |

| Digital Twin Platforms | Create virtual network replicas for scenario testing and optimization without operational risk. |

| Predictive Analytics | Identify patterns signaling future events, reducing forecasting errors 20% to 50%. |

| Blockchain | Enable end-to-end traceability through immutable records, valuable for pharmaceuticals and food safety. |

| Robotic Process Automation | Handle repetitive tasks like data entry and order processing, freeing humans for higher-value work. |

4. The Global Supply Chain’s Role in Supporting Everyday Consumer Behavior

The Global Supply Chain has shaped consumer expectations in ways most people never consciously recognize. It trained consumers to expect instant gratification, endless variety, and seamless convenience. The supply chain does not merely respond to behavior. It creates the conditions that make certain behaviors possible.

Consider two-day delivery that became standard in developed markets. This expectation emerged only because supply chains evolved to support it. Sophisticated warehouse networks positioned inventory closer to customers. Automated facilities accelerated processing. Predictive algorithms pre-positioned items before customers ordered them. People now abandon carts if delivery takes longer than expected.

Product variety exploded because global supply chains made it economically feasible. A grocery store stocks fruits from five continents and goods from dozens of countries. This variety feels natural now, but exists only because logistics systems can profitably move small quantities across vast distances.

Fast fashion demonstrates how supply chains enable new consumption patterns. Clothing retailers refresh inventory every few weeks. This speed depends on supply chains coordinating design teams in one country, fabric mills in another, and distribution from a third. Consumer behavior adapted to expect constant novelty at low prices.

E-commerce transformed shopping by making every store accessible from anywhere. But this convenience depends entirely on supply chain infrastructure. Warehouses near population centers enable fast delivery. Returns processes make online shopping feel risk-free. Customer expectations for online shopping are actually expectations about supply chain capabilities.

Cultural changes follow supply chain evolution. Year-round availability for seasonal produce changed diets. Overnight ordering changed gift-giving. The Global Supply Chain does not simply serve culture. It actively shapes what people consider normal and desirable.

Global Supply Chain Impact on Consumer Behavior

| Consumer Expectation | Supply Chain Enabler |

|---|---|

| Fast Delivery | Proximity warehousing places inventory near populations; automated sortation processes millions of packages daily. |

| Product Variety | Global sourcing networks connect specialized producers with dispersed consumers economically. |

| Always Available | Just-in-time replenishment and real-time data trigger automatic reordering to prevent stockouts. |

| Low Prices | Manufacturing economies of scale, efficient logistics, and competition among global suppliers drive costs down. |

| Easy Returns | Reverse logistics networks handle returns efficiently with prepaid shipping and automated refund processing. |

| Personalization | Data analytics identify preferences while flexible manufacturing produces customized variations economically. |

5. How the Global Supply Chain Reinvents Itself Through Crises and Change

Crisis acts as an accelerant for evolution in the Global Supply Chain. Each major disruption reveals weaknesses, forces adaptation, and drives innovation that persists long after the threat passes. The system emerges different, usually more resilient and sophisticated.

The COVID-19 pandemic provided a master class in vulnerability and adaptation. Factory closures in China rippled through global manufacturing within weeks. Yet the response demonstrated remarkable adaptability. Companies diversified suppliers, increased safety stock, and redesigned networks for resilience. By 2025, supply chain disruptions had fallen to approximately $184 billion in annual losses, representing an 88% reduction from peak crisis levels.

However, recovery remained incomplete. Average raw material delivery time stood at 81 days compared to 65 days pre-pandemic. Approximately 76% of European shippers reported disruptions during 2024, with 25% encountering over 20 disruptive events. Companies now face disruptions costing around 8% of annual revenues on average.

Near-shoring emerged as a major strategic response. Companies moved production closer to end markets to reduce transportation risks. Mexico and Vietnam became key manufacturing hubs. Manufacturing executives reported 71% wanting increased US-based production, while 51% pursued near-shoring strategies. This geographic rebalancing represents one of the most significant supply chain transformations in decades.

Automation accelerated dramatically as labor shortages mounted. The global logistics automation market projects growth at 14.7% annually from 2024 to 2030. Warehouse robotics and AI-powered management became essential investments rather than optional upgrades.

Risk management practices evolved beyond insurance. Companies invested in visibility tools providing real-time views into lower-tier suppliers. Spending on IT for supply chain applications increased for 82% of organizations. Scenario planning using digital twins allowed testing responses before crises occurred.

The transformation continues accelerating. Efficiency remains important, but resilience now shares equal billing. Crisis did not break the system. It forced evolution that makes it more adaptable for an uncertain future.

Global Supply Chain Crisis Adaptations

| Adaptation Strategy | Implementation and Impact |

|---|---|

| Nearshoring | Production relocated closer to end markets, with Mexico and Vietnam emerging as major manufacturing hubs. |

| Supplier Diversification | Multiple sources qualified for critical inputs with explicit geographic diversity requirements. |

| Inventory Strategy Changes | Just-in-time gave way to just-in-case with higher safety stock despite increased carrying costs. |

| Digital Transformation | IT spending increased across 82% of organizations for real-time visibility and early warning systems. |

| Automation Expansion | Logistics automation market growing 14.7% annually as companies reduce labor dependency. |

| Circular Economy Integration | Product design now considers end-of-life recovery, creating alternative material sources. |

6. How the Global Supply Chain Shapes the Future of Global Growth and Innovation

The next wave of technological progress depends more on supply chain capabilities than most people realize. The Global Supply Chain does not simply support innovation. It determines which technologies can scale, which products reach markets, and which breakthroughs remain lab curiosities.

Clean energy transition illustrates this dependency dramatically. Battery production needs massive quantities of lithium, cobalt, and nickel from geographically concentrated sources. Supply chain bottlenecks, not technology limits, constrain how fast renewable energy can replace fossil fuels. Building supply infrastructure for electric vehicle fleets requires mining operations, processing facilities, and recycling systems that will take decades to fully develop.

AI hardware faces similar constraints. Training large AI models requires specialized chips produced in limited facilities. As AI capabilities advance, demand for computing power grows exponentially. Innovation in AI software runs ahead of the supply chain’s ability to provide necessary hardware.

Biotechnology and personalized medicine depend on supply chains with unprecedented precision. Cell therapies need cold chain logistics maintaining exact temperatures continuously. Gene therapies require traceability systems tracking individual doses. Healthcare innovations will remain inaccessible unless supply chains evolve to handle their complexity affordably.

Economic growth in developing nations hinges on supply chain access. Countries integrating into global networks gain access to markets, technologies, and capital accelerating development. Those excluded or peripheral struggle to industrialize. The structure of the Global Supply Chain influences which nations prosper.

The digital economy relies entirely on physical supply chains most users never see. Cloud computing depends on data centers filled with globally manufactured servers. Even purely digital services depend on infrastructure built and maintained through complex logistics.

Looking forward, the Global Supply Chain will increasingly determine competitive advantages between nations and companies. Those who design, control, or optimize key supply networks will capture disproportionate value. New technologies will emerge first in regions with infrastructure to support them and scale fastest where supply chains deliver components reliably.

Global Supply Chain Innovation Enablers

| Innovation Domain | Supply Chain Requirements |

|---|---|

| Clean Energy | Battery production requires massive lithium, cobalt, nickel scaling; solar depends on concentrated polysilicon supply. |

| AI Hardware | Advanced semiconductor capacity must expand; memory and storage must scale for massive data requirements. |

| Biotechnology | Cold chain logistics maintain precise temperatures; personalized medicine requires individual dose traceability. |

| Space Commerce | Launch services must become routine and affordable; materials need reliable orbital delivery systems. |

| Quantum Technologies | Specialized materials with extreme purity standards require dedicated supply chains and ultra-low temperature systems. |

| Synthetic Biology | Living materials need specialized handling; biosafety requirements constrain routing and storage options. |

Conclusion: Why the Global Supply Chain Will Define the World Ahead

The Global Supply Chain has become more than logistics infrastructure. It operates as the central nervous system of civilization, coordinating economic activity across every border. Its influence extends into geopolitics, innovation, sustainability, and human behavior.

The perpetual motion that defines this system creates both fragility and resilience. Dependencies between nations create opportunities for cooperation but potential for conflict. Intelligence and prediction allow proactive management but require massive technology investments. Consumer expectations shaped by supply capabilities drive demand patterns the system must satisfy. Crisis forces adaptation that makes networks more sophisticated.

These tensions will intensify. Climate change threatens key production regions and routes. Geopolitical competition fragments networks optimized for efficiency. Technological disruption creates new requirements faster than supply chains can adapt. Resource constraints limit materials available for growing demand.

Yet the Global Supply Chain will continue evolving because it must. Economic growth depends on goods moving efficiently. Innovation requires materials delivered reliably. Human welfare relies on access to products that supply networks enable. Adaptation becomes the permanent condition.

Nations that build resilient supply chains will prosper. Companies that master supply chain complexity will dominate. Technologies solving supply chain challenges will capture enormous value. Workers developing supply chain expertise will remain employable as automation advances.

This system deserves more attention than it typically receives. Most people notice it only when it fails. But the Global Supply Chain operates constantly in the background, shaping possibilities defining modern life. Understanding its dynamics provides insight into economic trends, political conflicts, technological progress, and social change.

The Global Supply Chain represents one of humanity’s greatest collaborative achievements. Millions coordinate across languages and cultures to move goods where needed. This decentralized coordination demonstrates human capability for cooperation at planetary scale.

Looking ahead, the Global Supply Chain will face demands unlike any in history. Supporting ten billion people sustainably requires radical transformation. Responding to climate change demands fundamental redesign of energy and materials systems. Managing geopolitical competition without fragmenting into closed blocs requires new cooperation. These challenges will test whether the system can adapt fast enough.

The silent architecture that moves our world deserves recognition for what it is: a living system of staggering complexity and fundamental importance. The Global Supply Chain connects past to present and present to future. Understanding this system means understanding forces shaping the next generation of human experience. That power, quiet and persistent, makes it one of the most consequential forces shaping the century ahead.

Global Supply Chain Future Determinants

| Future Factor | Supply Chain Influence |

|---|---|

| Sustainability Transition | Network redesign determines decarbonization pace; companies achieving 12% carbon reductions demonstrate viable pathways. |

| Technological Advancement | Hardware availability constrains software innovation; component capacity determines which technologies scale from research to deployment. |

| Economic Development | Nations integrate into global economy through supply chain participation; peripheral countries face structural industrialization barriers. |

| Geopolitical Stability | Economic interdependence creates cooperation incentives but also conflict potential through strategic dependencies. |

| Resource Availability | Critical material shortages constrain production; concentrated sources create vulnerabilities requiring recycling and substitution. |

| Labor Markets | Workforce availability determines capabilities; aging populations increase automation while emerging markets provide manufacturing labor. |